Maximizing Natural Light Through an Insulating Polycarbonate Façade System: A Danpatherm System Case Study

In the ever-evolving realm of architectural design, the insulating polycarbonate façade system has emerged as a game-changer. This article explores the remarkable capabilities of these systems, with a spotlight on Danpal’s Danpatherm System, a double high insulation solution designed to illuminate spaces naturally and efficiently. We will also draw inspiration from the renowned “Bangholm Outdoor Centre” project by Holmes Miller Architects, showcasing the transformative power of Danpatherm combined with Danpalon Panels.

Understanding the Significance of the Insulating Polycarbonate Façade System

In the realm of modern architecture, comprehending the profound significance of the insulating polycarbonate façade system is paramount. These systems, a testament to innovation and sustainability, redefine how natural light interacts with interior spaces. As we delve deeper into the architecture of light, we explore the unique attributes of insulating polycarbonate panels and, specifically, Danpal’s Danpatherm system.

This exploration illuminates the transformative potential of these panels, creating environments that seamlessly blend aesthetics, functionality, and sustainability. By embracing the insulating façade system, architects unlock the ability to design spaces that not only capture the essence of natural light but also set new standards in energy efficiency and architectural excellence.

The Versatile Properties of Polycarbonate Panels

Exploring the versatility of polycarbonate panels reveals a world of architectural possibilities. These panels have become a go-to choice for architects and builders seeking a harmonious blend of form and function. Their remarkable attributes, including exceptional light transmission, UV resistance, and thermal insulation properties, have redefined how we approach sustainable architectural design. Furthermore, their lightweight yet robust nature grants architects the creative freedom to experiment with various design styles, all while upholding structural integrity.

As we delve into the realm of polycarbonate panels, we unveil the potential they hold for architectural projects, enhancing both aesthetics and energy efficiency. Within this context, we’ll also delve into Danpal’s Danpalon system, a cutting-edge solution that pushes the boundaries of what’s achievable in contemporary architecture.

Introducing Danpatherm System – A Game-Changer in Natural Lighting

Prepare to be introduced to Danpatherm System, a visionary innovation that stands as a cornerstone in the world of architectural design. More than just an insulating polycarbonate façade system, Danpatherm represents a transformative leap forward in the pursuit of natural lighting excellence. At its core, Danpatherm offers unparalleled thermal insulation, ensuring optimal energy efficiency and reduced operational costs for buildings. Its hallmark, however, lies in its capacity to effortlessly diffuse natural light, creating interiors that are not only illuminated but also bathed in a soft, soothing glow.

But the true beauty of Danpatherm is its versatility. Architects have the freedom to incorporate Danpatherm panels into an array of design styles, from curved to flat surfaces, all while maintaining structural integrity. Constructed with premium materials, Danpatherm panels are designed to withstand the test of time, offering longevity and minimal maintenance requirements.

In essence, Danpatherm System redefines the boundaries of architectural possibility, offering architects and builders a revolutionary tool to craft spaces that prioritize aesthetics, sustainability, and functionality with natural light as the centerpiece.

Key Features of Danpatherm:

- Superior Insulation: Danpatherm delivers remarkable thermal insulation, ensuring energy efficiency and reduced operational costs for buildings.

- Flexibility in Design: Architects have the creative freedom to implement Danpatherm panels into various design styles, and without compromising structural integrity.

- Optimal Light Diffusion: Danpatherm panels disperse natural light evenly throughout interior spaces, eliminating harsh glare and creating a comfortable environment.

- Enduring Durability: Constructed with premium materials, Danpatherm panels are built to withstand the test of time, offering longevity and minimal maintenance requirements.

- Sustainability: By harnessing natural light and reducing reliance on artificial lighting, Danpatherm contributes to greener and more sustainable architectural practices.

The Bangholm Outdoor Centre – A Shining Example of Danpatherm’s Potential

The Bangholm Outdoor Centre, designed by Holmes Miller Architects, exemplifies the transformative impact of Danpatherm’s insulating polycarbonate façade system. For this project, Danpal’s Danpatherm system was selected to construct the sports hall and gym hall, with Danpalon Panels in “Softlite Opal” and “Softlite Clear” colors. The decision to use Danpatherm and Danpalon Panels was rooted in their outstanding properties, perfectly aligning with the project’s objectives.

Danpatherm’s contribution to the Bangholm Outdoor Centre:

- Abundant Natural Light: The integration of Danpatherm and Danpalon Panels flooded the sports and gym halls with natural light, creating an inviting and dynamic atmosphere.

- Energy Efficiency: The superior thermal insulation properties of Danpatherm aided in maintaining optimal indoor temperatures, reducing the need for excessive heating or cooling.

- Aesthetic Appeal: The soft, diffused light created by Danpatherm panels enhanced the visual appeal of the spaces, making them more inviting for athletes and visitors alike.

- Sustainability: By leveraging the power of natural light, the Bangholm Outdoor Centre significantly reduced its energy consumption and carbon footprint.

Final Words:

In the world of architecture, the marriage between innovation and aesthetics is an ever-evolving journey. The insulating polycarbonate façade system, exemplified by Danpatherm System and showcased through the Bangholm Outdoor Centre project illuminates this path. The harmonious fusion of natural light, energy efficiency, and sustainability is not merely a goal but a reality attainable through Danpal’s solutions. Explore the possibilities of Danpatherm and Danpalon Panels to bring your architectural visions to radiant life.

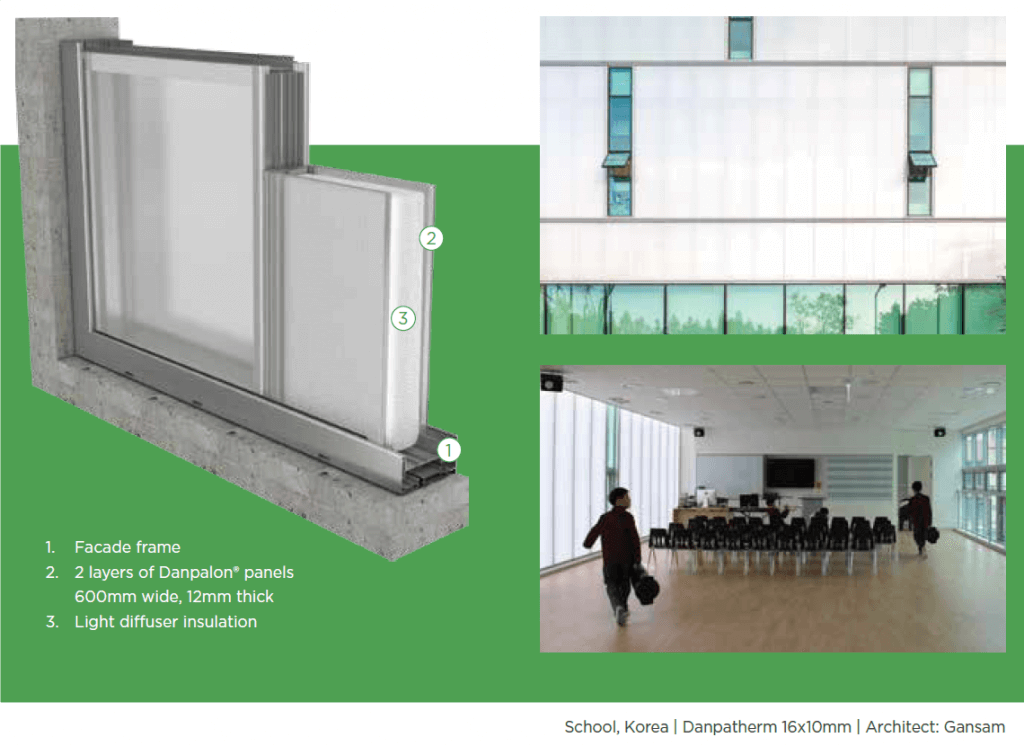

Let’s take a step back for a moment, so we can understand what sets the K7 and K12 façade solution, apart from other translucent offerings. The Danpatherm design concept relies on the implementation of fully finished off pre-fabricated cassettes, which are flanked by

Let’s take a step back for a moment, so we can understand what sets the K7 and K12 façade solution, apart from other translucent offerings. The Danpatherm design concept relies on the implementation of fully finished off pre-fabricated cassettes, which are flanked by